20+

Core invention patents

Business Unit

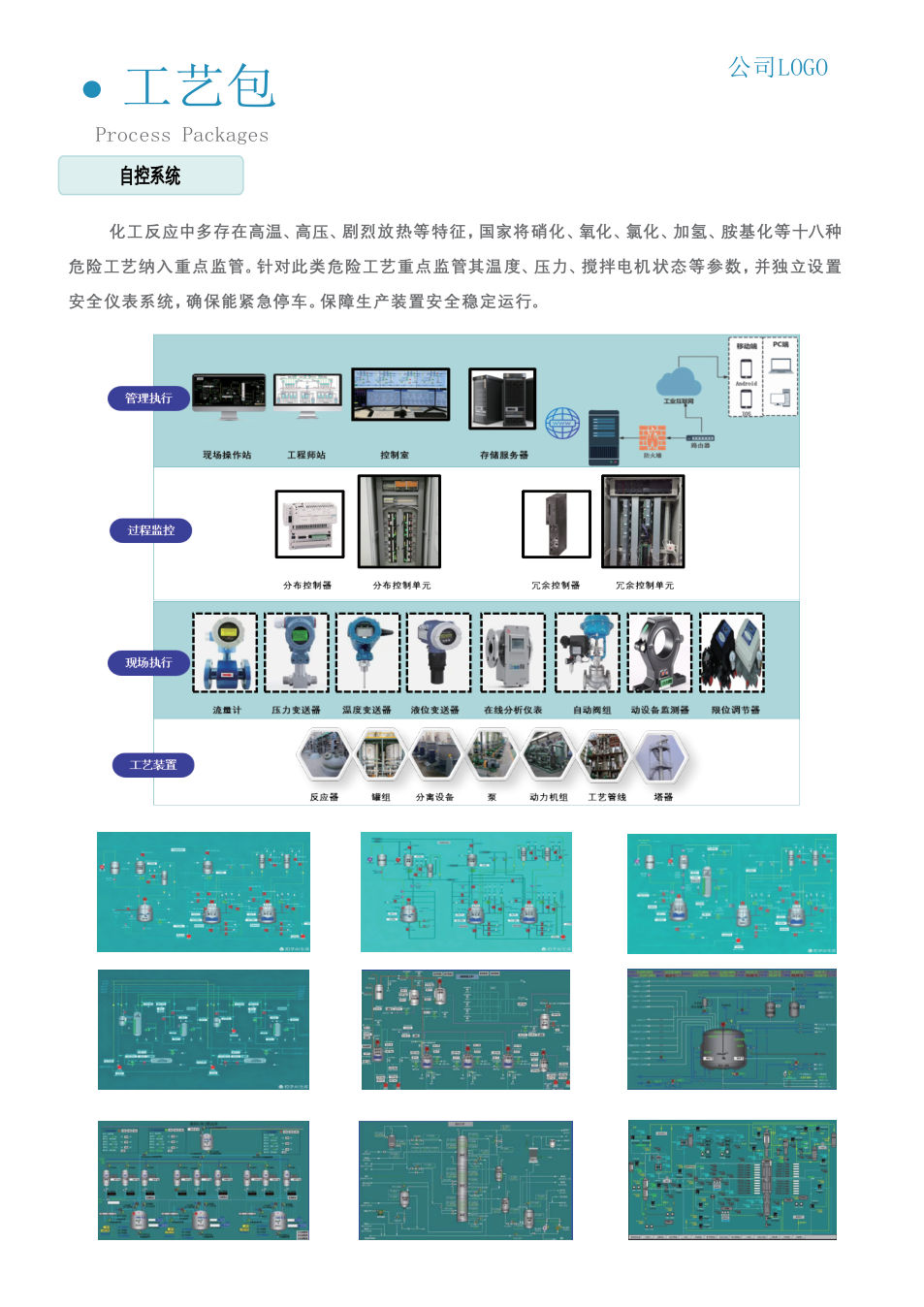

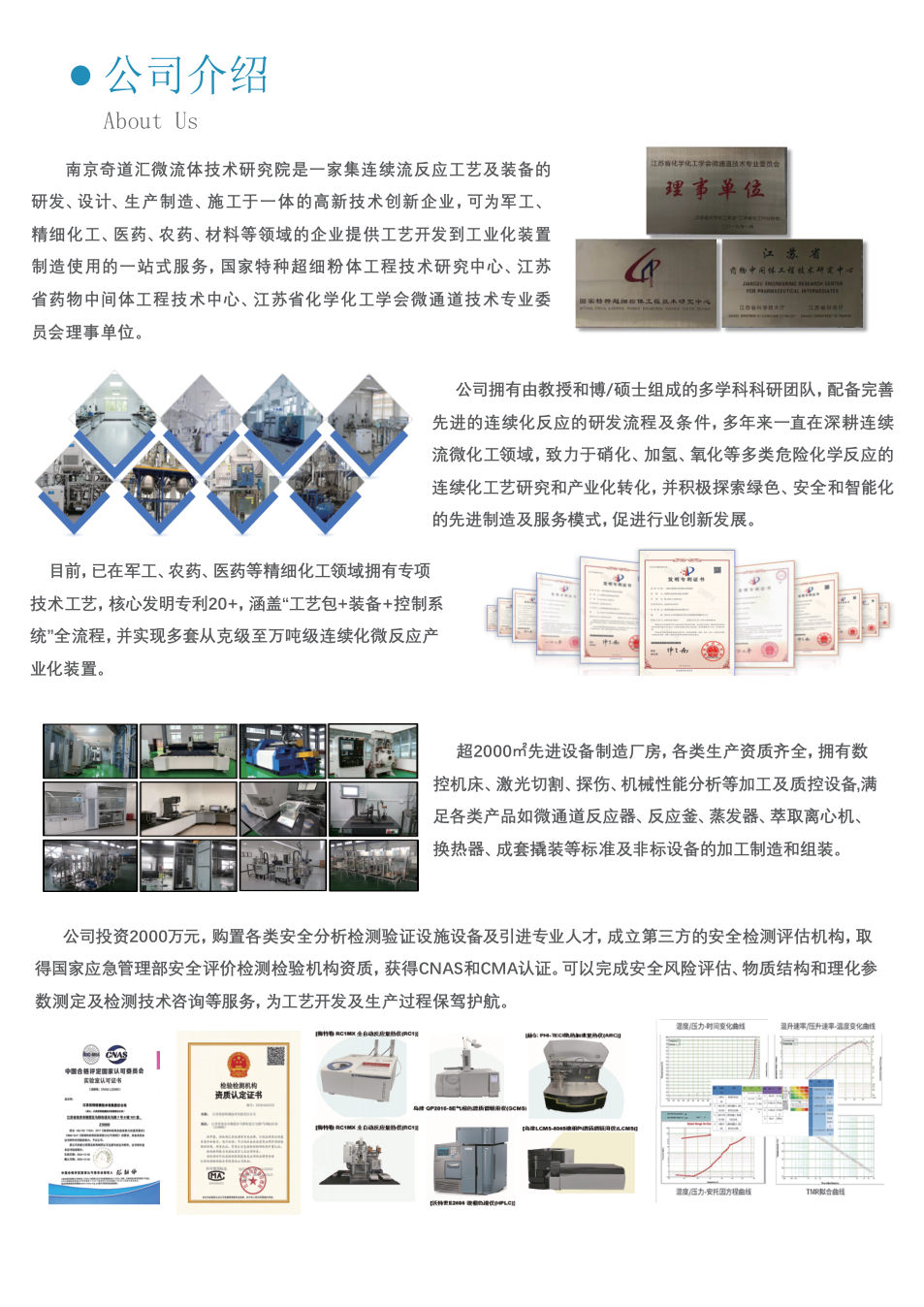

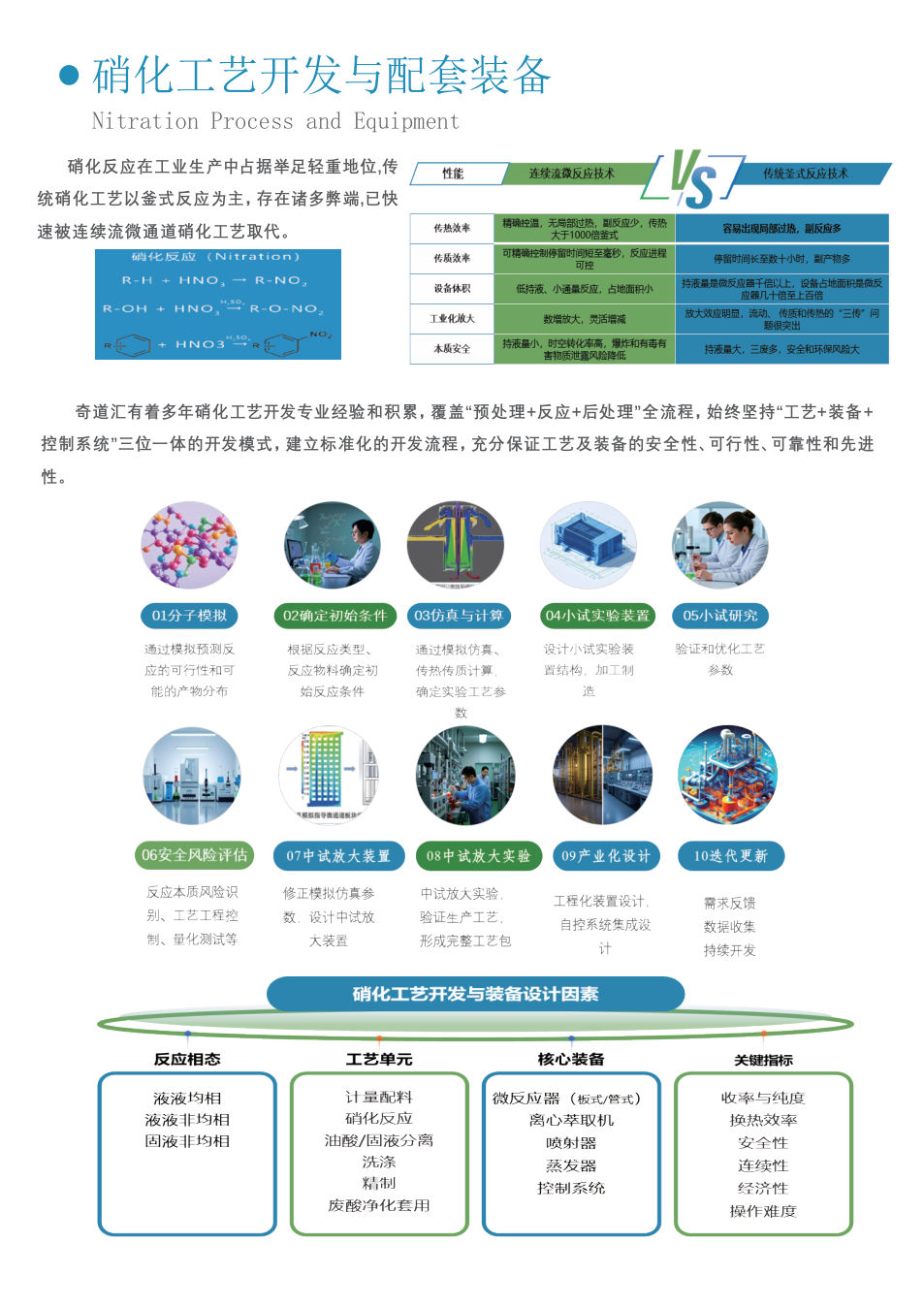

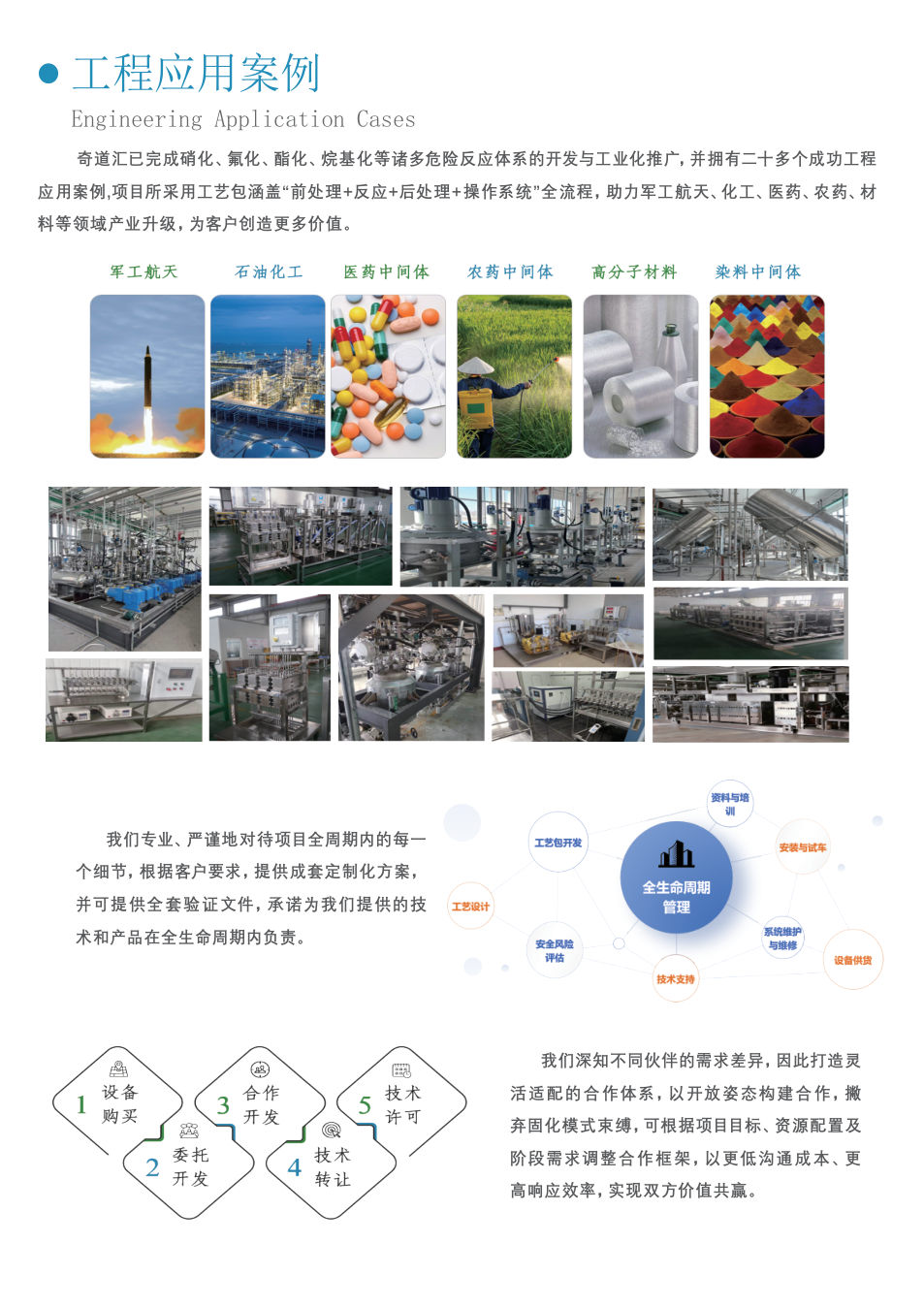

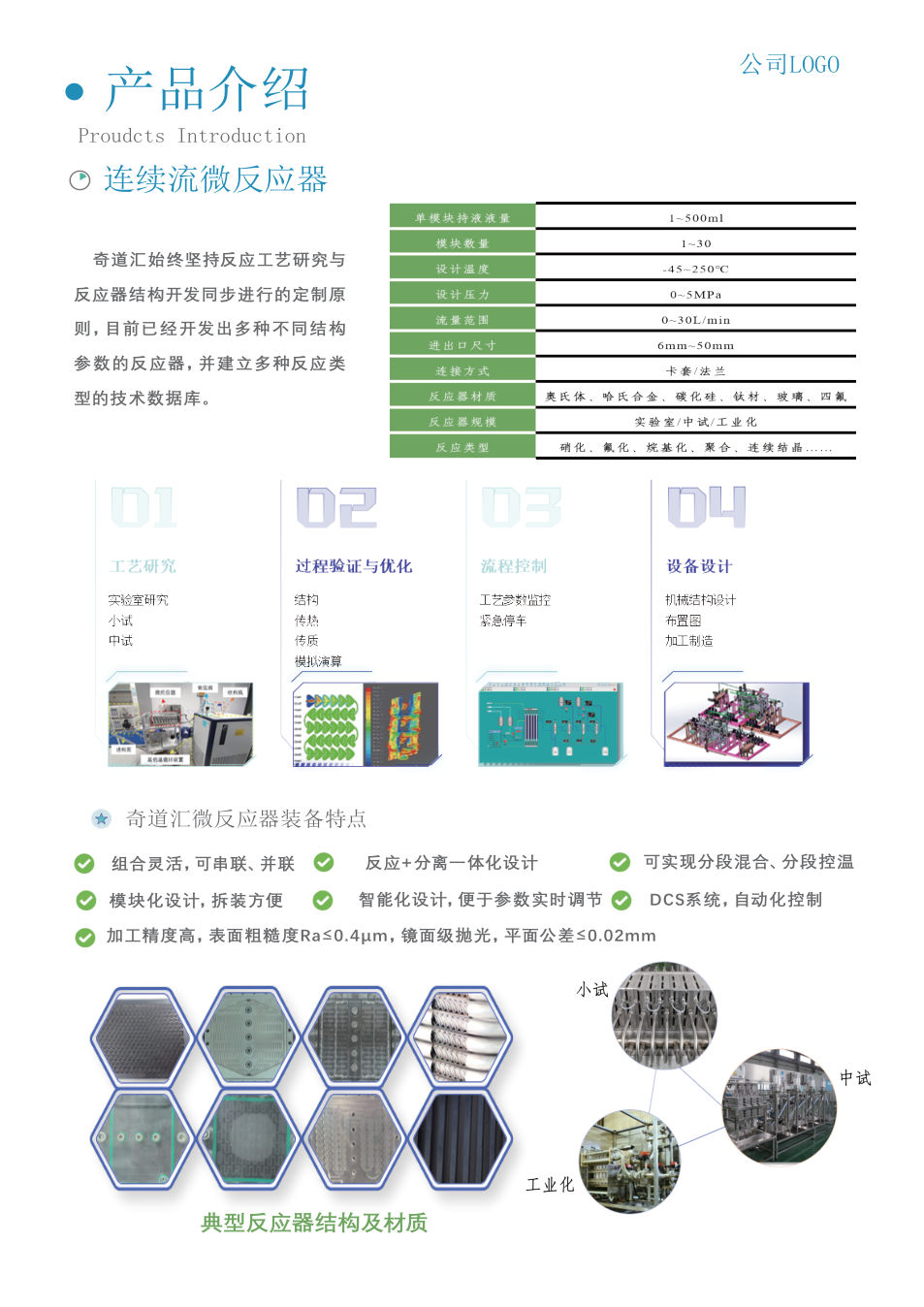

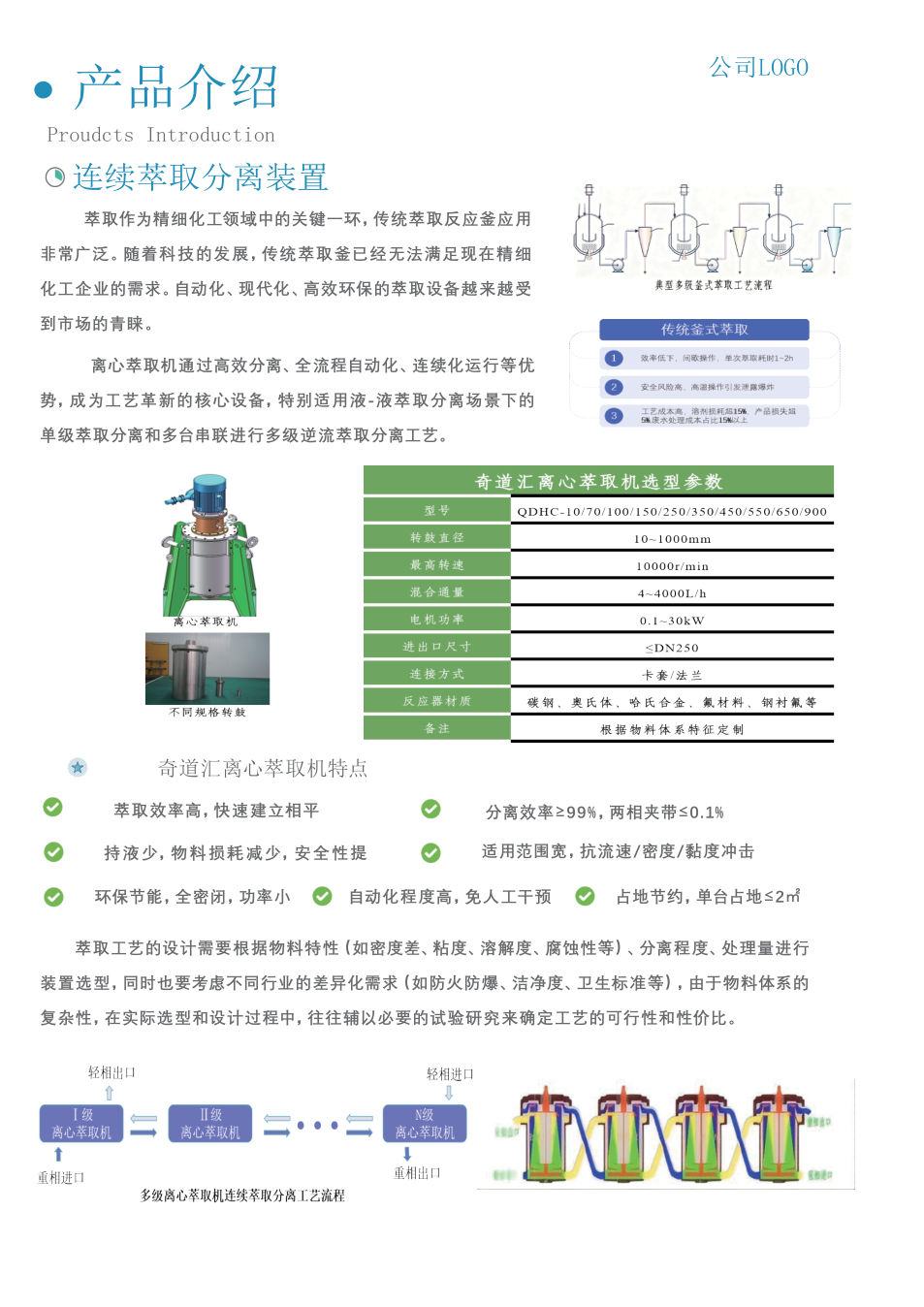

Integrated solutions for hazardous-reaction continuous processing, covering process development, equipment engineering, automation control, and industrial implementation.

Qidaohui focuses on continuous-flow microchemical technology for high-risk reaction systems, serving fine chemicals, pharmaceuticals, agrochemicals, and advanced materials sectors.

Core invention patents

Manufacturing and testing space

Industrial application projects

Scale-up delivery experience

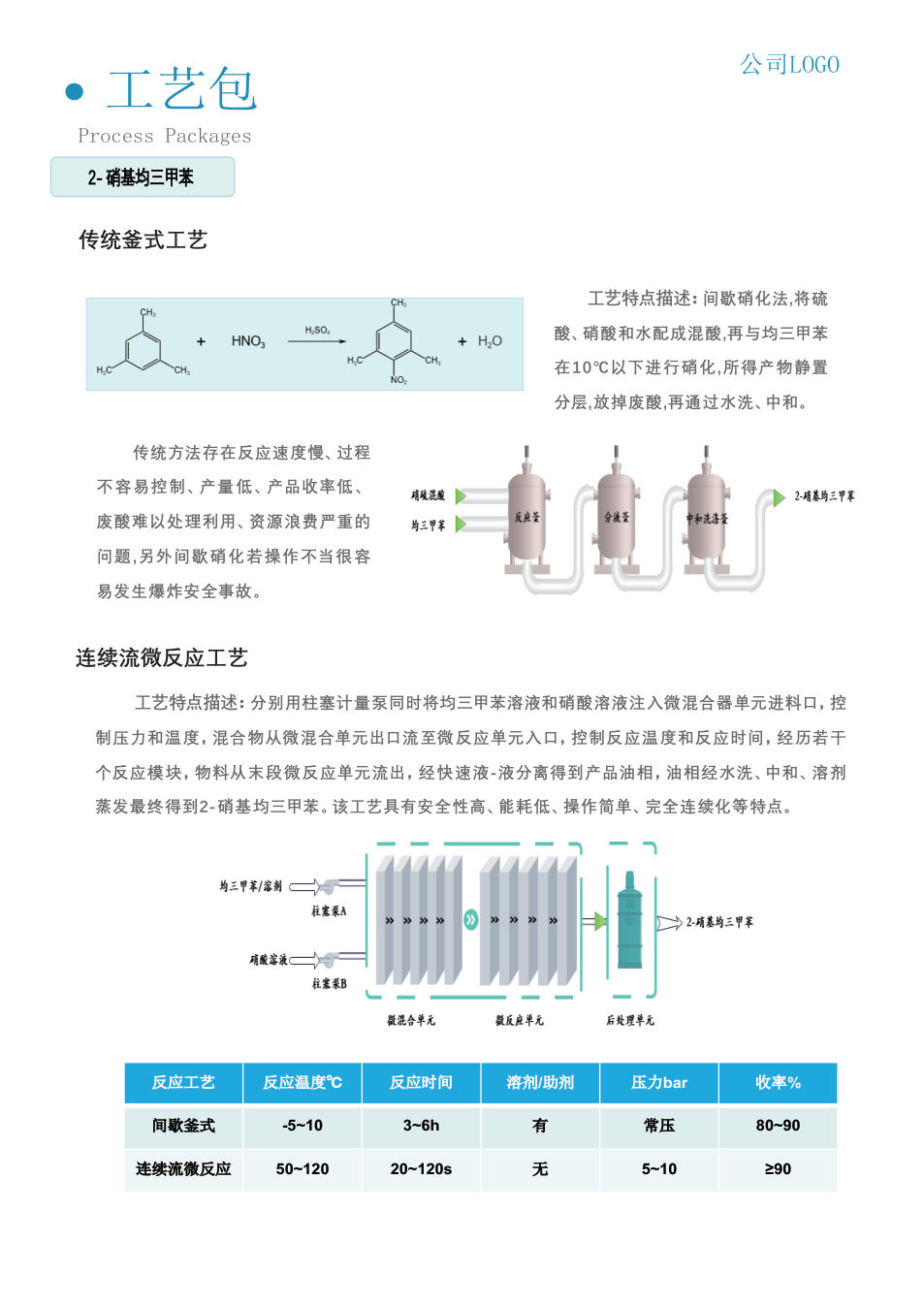

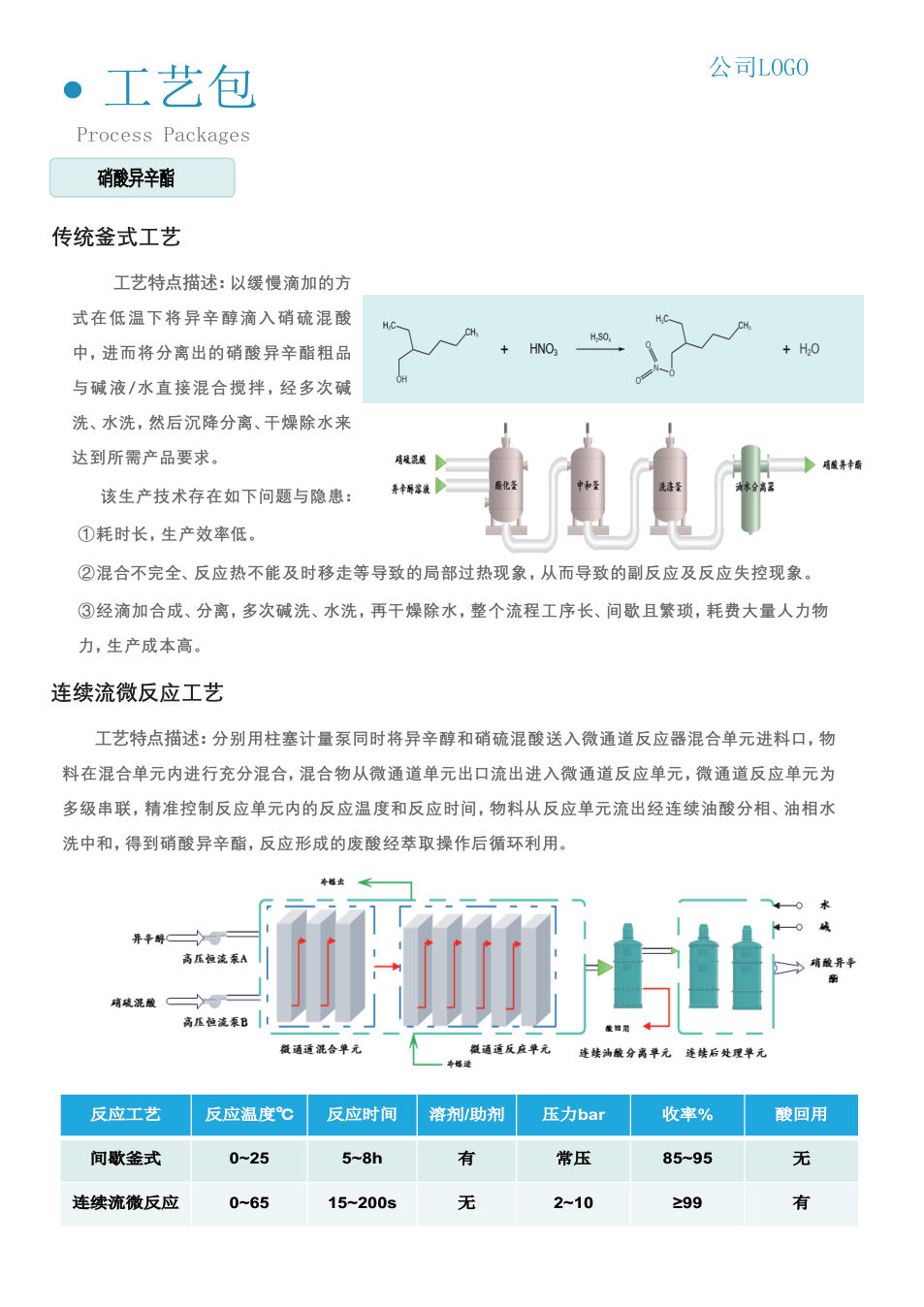

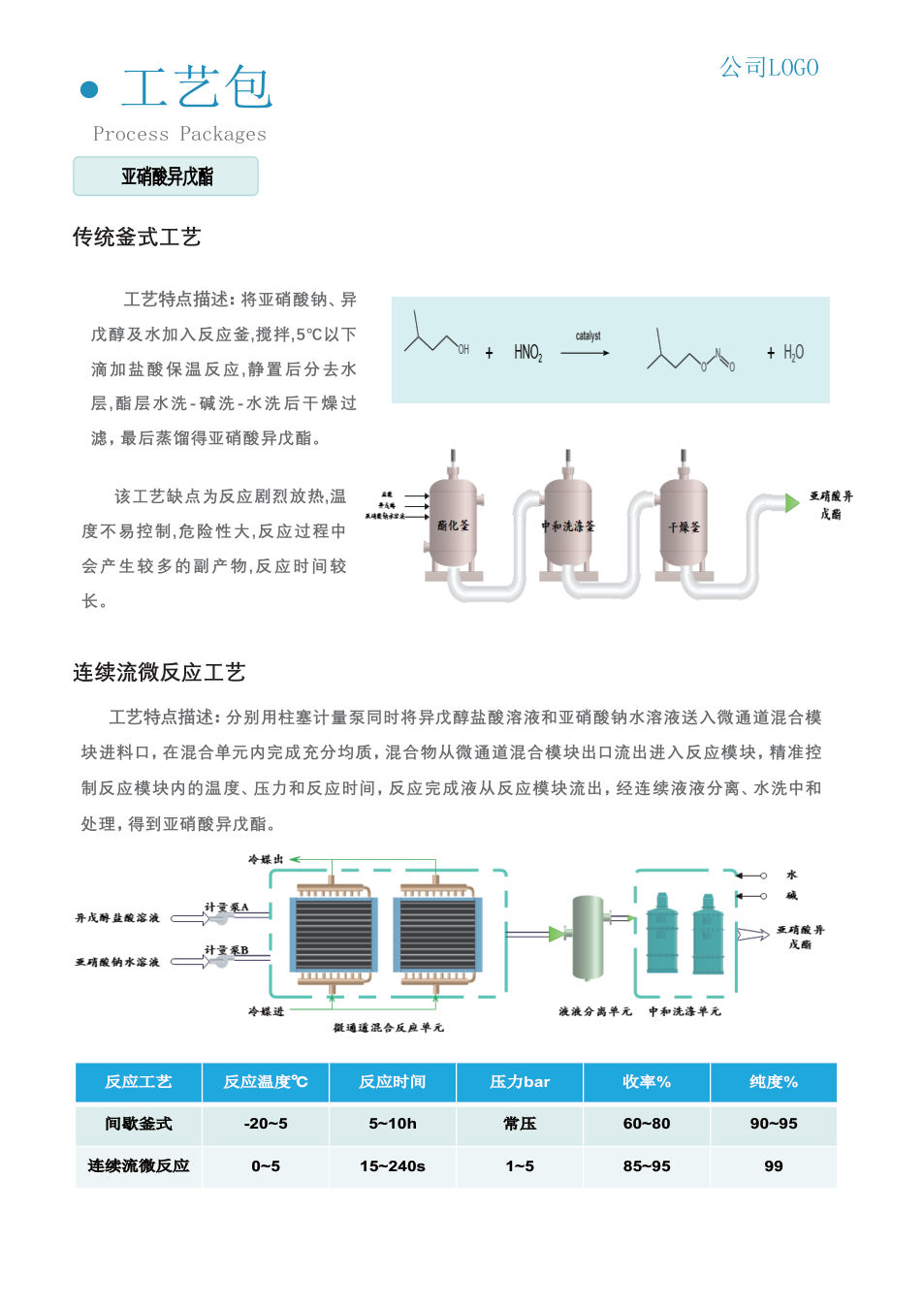

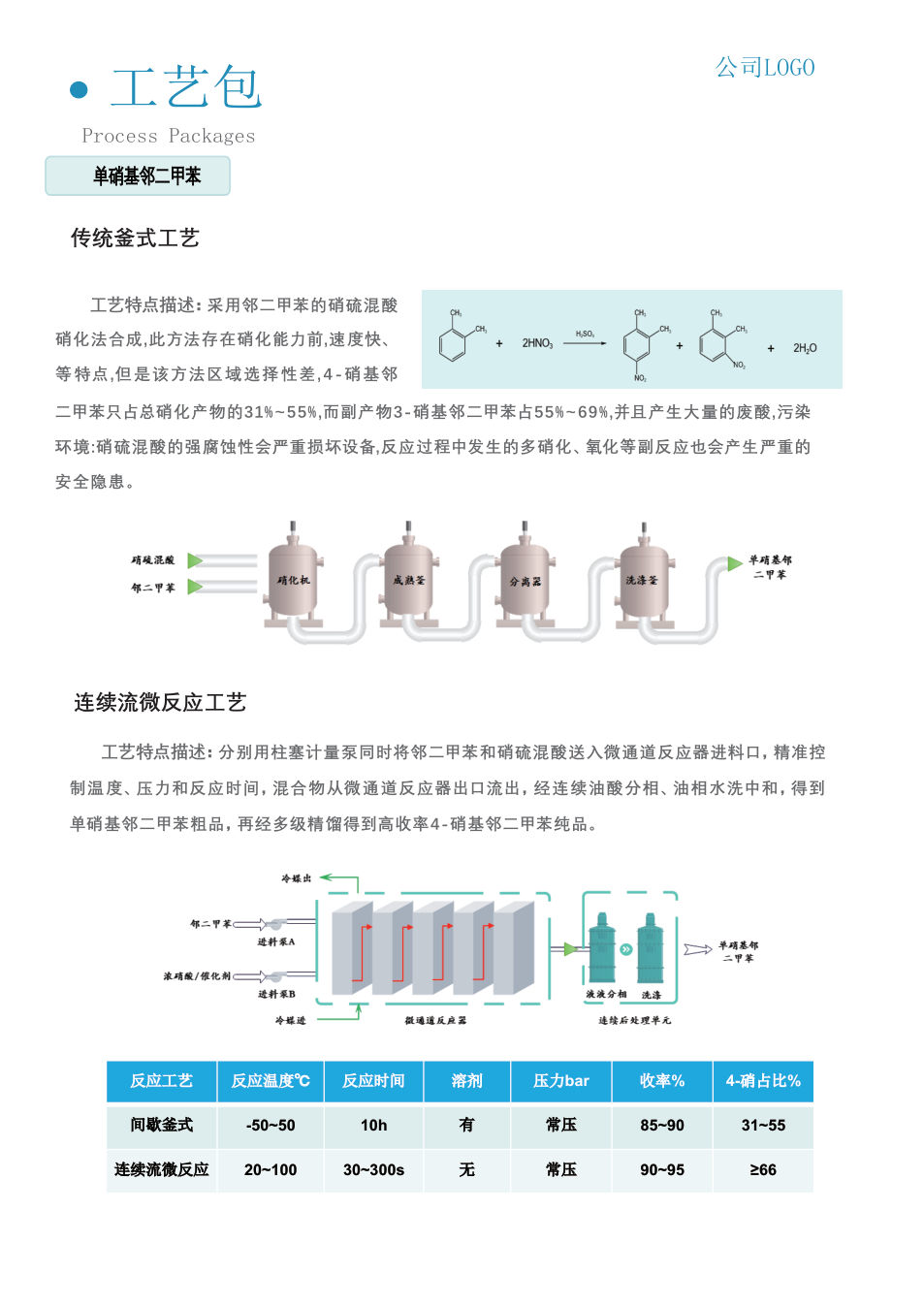

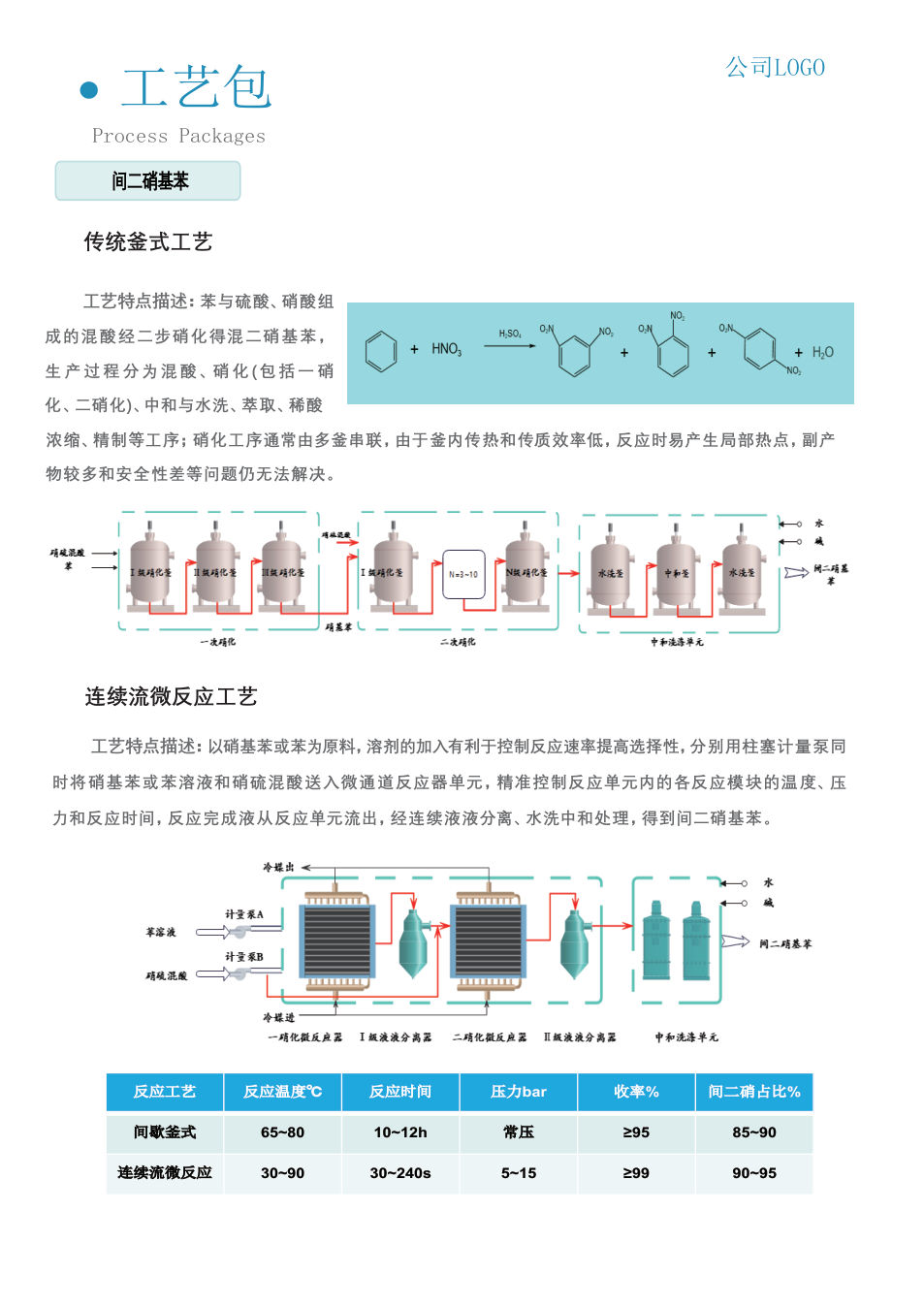

| Scenario | Batch Route | Continuous Route |

|---|---|---|

| Isooctyl Nitrate | Cycle 5~10h with multiple batch operations | 15~240s reaction window with continuous operation |

| 2-Nitromesitylene | Low-temp dropwise route with long manual sequence | Pumped feed + micro-mixing + rapid phase separation |

| Safety Control | Higher local hotspot and runaway risk | Real-time temp/pressure supervision with interlocks |